The C-Netics enables non-destructive, continuous monitoring of cell viability and cell density, providing a live window into what’s happening inside the bioreactor. By eliminating manual sampling and reducing contamination risks, our technology helps optimize critical parameters, accelerate decision-making, and maximize process efficiency.

Fewer manipulations, more insights, lower bioprocessing costs.

Closed system ensures sterile, contamination-free measurements.

Preserve product integrity with non-invasive, live analysis.

Accurate results from continuous in-process cell monitoring.

The C-Netics is designed for simplicity and flexibility, it connects to any bioreactor, regardless of size or brand, and is ideal for mammalian cells in suspension. Whether in R&D or GMP settings, integrating real time monitoring into your process has never been easier.

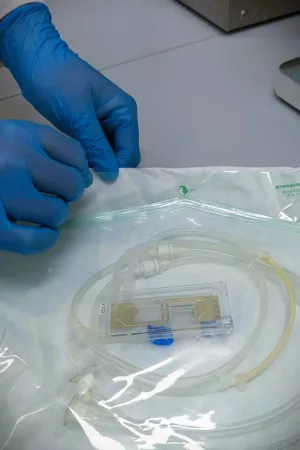

After opening the sterile single-use kit, setup takes just 3 steps:

1. Connect the kit to your bioreactor using a sterile tube welder.

2. Insert the microfluidic cartridge into the C-Netics slot.

3. Start the automated workflow.

From there, C-Netics continuously monitors your batch, delivering accurate cell viability and cell density data in real time, with no manual calibration required.

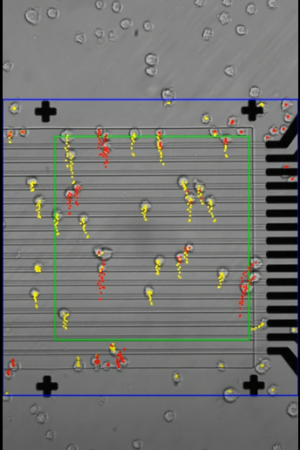

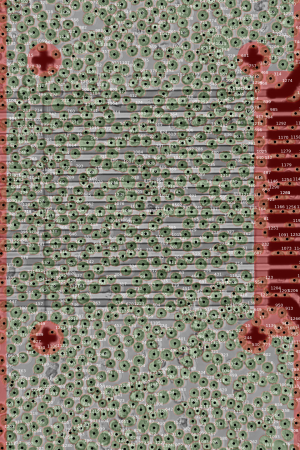

The C-Netics combines high-resolution microscopy, microfluidics, dielectrophoresis, and AI-powered analysis to deliver real-time insights into cell health. As cells flow through our patented microfluidic cartridge equipped with high-end microelectrodes, a dielectrophoretic field is applied to induce movement. Each cell’s individual speed and behavior on the electrodes are tracked. As cell viability decreases, cells typically shrink and move more slowly. Simultaneously, microscopy captures high-resolution images, allowing the extraction of detailed morphological parameters. All cell detection and tracking are performed automatically using proprietary AI models developed by Ceidos, providing robust, continuous measurement of cell viability and density throughout the bioreactor run without the need for manual sampling or calibration.

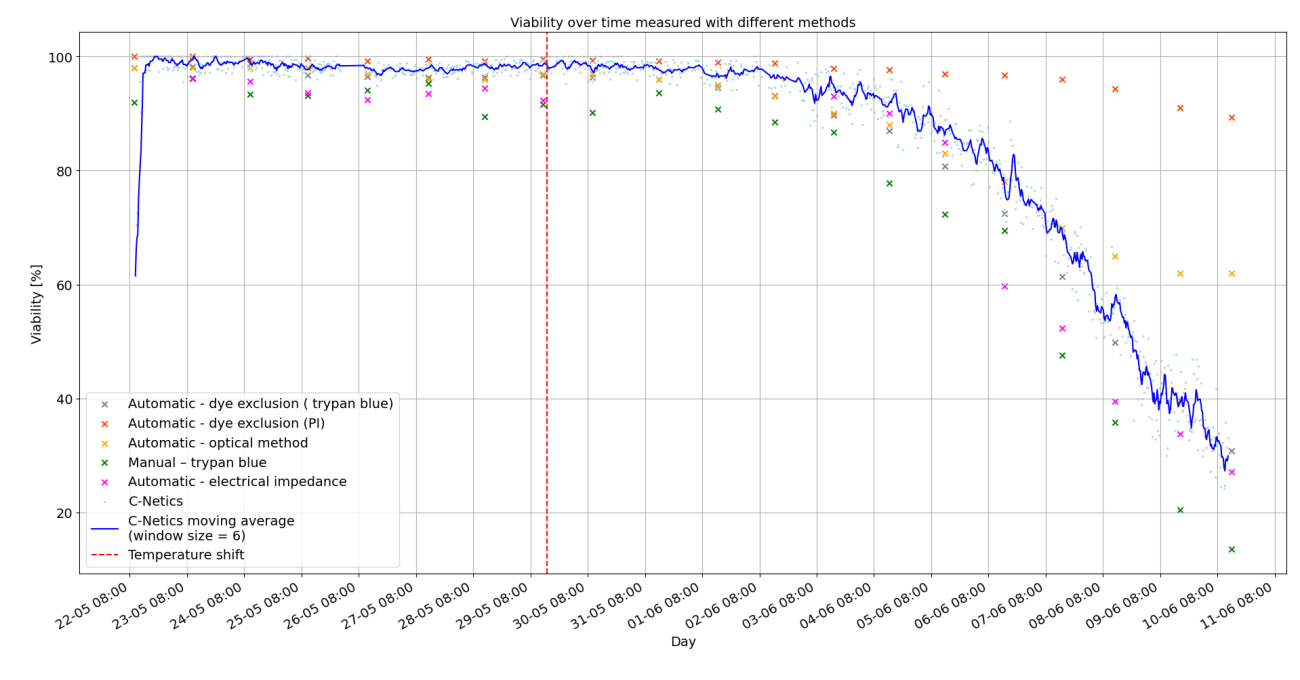

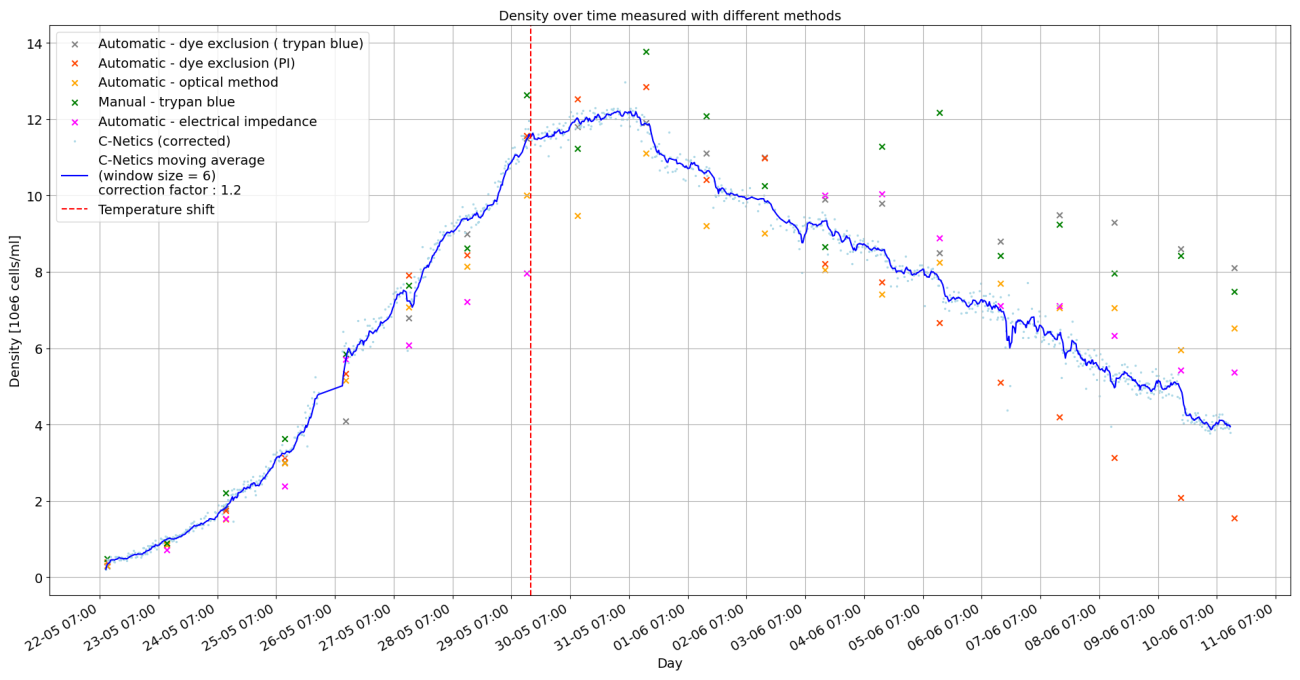

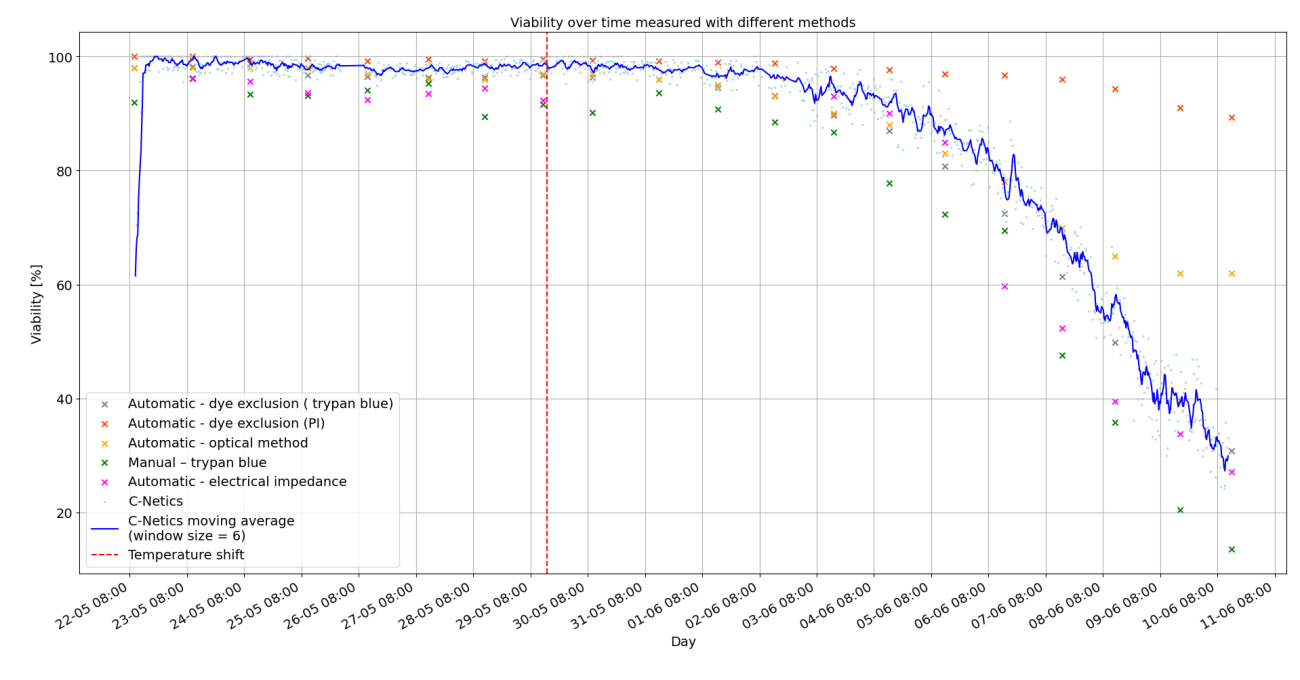

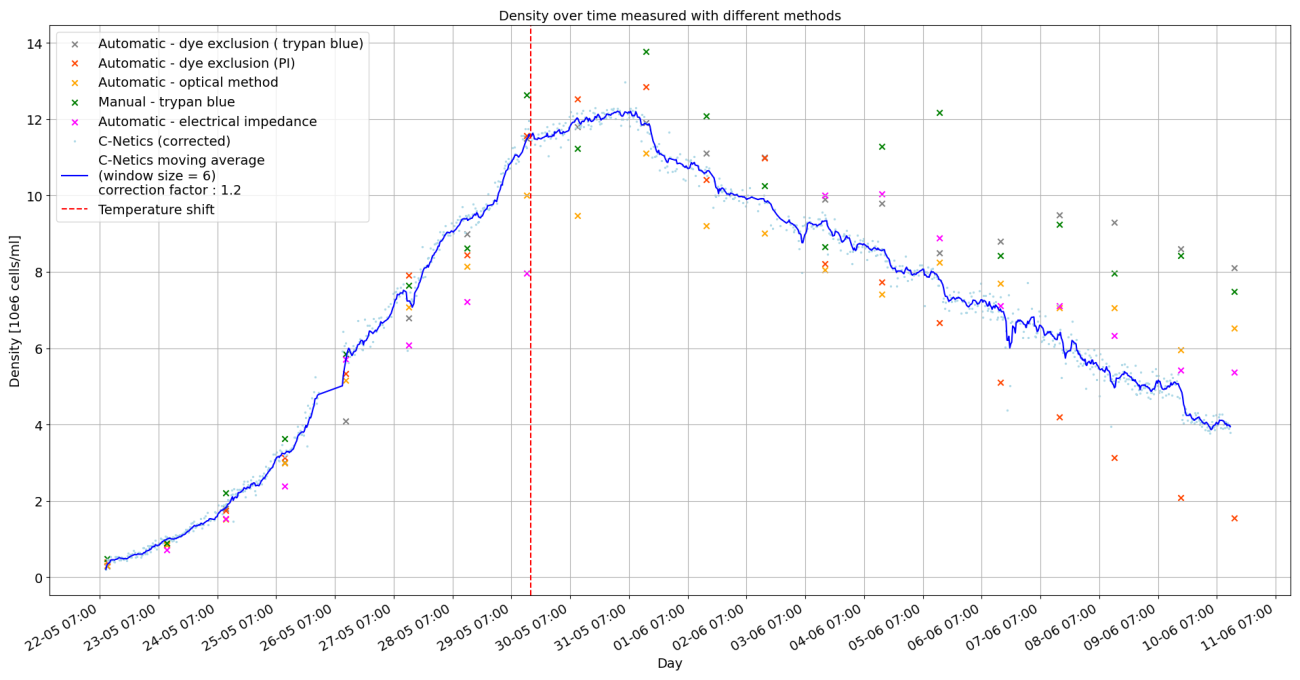

The graphs show real-time data generated by C-Netics over a 20-day run, compared to daily measurements using standard methods.

The connection to the bioreactor is quick, safe and convenient and allows the C-Netics to deliver density and viability measurements comparable with gold standard methods, offering the crucial advantage of eliminating the need for sampling by providing in-line measurements. Unlike other analyzers that contend with challenges such as dilution requirement, detection errors, and calibration issues, the C-Netics excels in effectively distinguishing cells from debris and consistently providing precise results. This underscores the C-Netics as a valuable tool for continuous and accurate monitoring in bioprocessing environments, providing real-time data collection and analysis to enhance production efficiency and ensure rigorous quality control.